Hydrophobic PTFE Membrane Pleated Cartridges are constructed with high-quality naturally hydrophobic PTFE membrane as well as polypropylene support layers and components. PTFE membrane pleated cartridges provide better hydrophobicity compared to polypropylene pleated filters commonly used in compressed air filtration, making them ideally suited for gas/vent applications. PTFE membrane cartridges have wide chemical compatibility and excellent temperature endurance, thus being good filtering for less aggressive processes and high cleanliness applications.

| Product name: | PTFE Hydrophobic Pleated Filter Cartridge |

|---|---|

| Media: | Hydrophobic PTFE membrane |

| Support/Diversion Layer: | PP |

| Shell/Center Rod/End Cap: | PP |

| Sealing material: | Silicone rubber, Ethylene-propylene rubber, Nitrile rubber, Fluorine rubber, Teflon rubber, Teflon-coated fluorine rubber |

| Length: | 10”、20”、30”、40″ |

| Outer diameter: | φ69 mm |

| Maximum operating temperature: | 80°C |

| Maximum working pressure difference: | 4 bar@ 21°C; 2.4 bar@80°C |

Hydrophobic PTFE Pleated Filter Cartridges Description

Hydrophobic PTFE Membrane Pleated Cartridges are constructed with high-quality naturally hydrophobic PTFE membrane as well as polypropylene support layers and components. PTFE membrane pleated cartridges provide better hydrophobicity compared to polypropylene pleated filters commonly used in compressed air filtration, making them ideally suited for gas/vent applications. PTFE membrane cartridges have wide chemical compatibility and excellent temperature endurance, thus being good filtering for less aggressive processes and high cleanliness applications.

Why Choose Ince’s Hydrophobic PTFE Pleated Filter Cartridge

Hydrophobic PTFE Pleated Filter Cartridge Details

Hydrophobic PTFE Pleated Filter Cartridge Features:

Hydrophobic PTFE Pleated Filter Cartridge Applications:

| Process Venting | Compressed Air & Gases | Fermentation Feed Air |

| Solvents | Aggressive Chemicals | Tank Vents |

| Hot DI Water | Strong Acids/Bases | Pharmaceutical Intermediates |

Hydrophobic PTFE Pleated Filter Cartridge Performance:

Operation Data for Hydrophilic PTFE Membrane Pleated Filters

| Maximum Operating Temperature | 90℃(194℉) |

| Max. Differential Pressure | 4.8 bar at 20℃(70 psi at 68℉) |

| 2.1 bar at 90℃(30 psi at 194℉) | |

| Recommended Change Out Differential Pressure | 2.4 bar (35 psid) |

| Sterilization Temperature Time | 121˚C (250˚F) for 30 minutes at 1.1 bar (14 psi), multiple cycles |

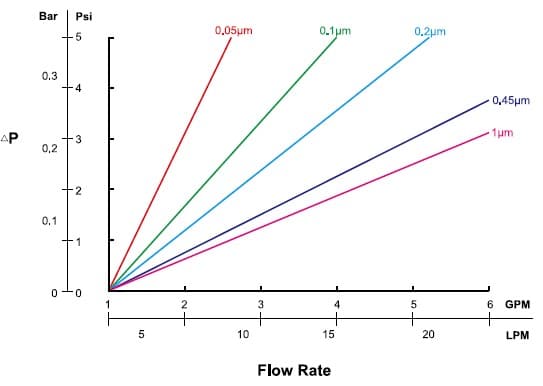

Pressure Drop Rate for 10″Hydrophilic PTFE Membrane Pleated Filters

End Caps of Hydrophobic PTFE Pleated Membrane Filter Cartridges:

MACROKUN has established long-term and stable cooperative relations with many transportation companies such as China Post, DHL, FEDEX, USPS, UPS, etc. Of course, MACROKUN can also provide air and sea transportation. The powerful logistics system enables all MACROKUN'S Printing Mesh, Filter Mesh and Filter Bags and so on to be easily and efficiently transported to any place. For quotes and inquiries, please email our sales team.